SAV’s Build & Test Center

At SAV Digital Environments, quality control and a commitment to the highest level of standards are two of the most important factors when it comes to the design, integration, and management of our home and business technologies. These two factors are only as successful as the skilled craftsman, the care, and the appropriate time that we put into each and every project. That is why we are always looking for new, innovative ways, to improve upon our abilities and knowledge. To that end, we humbly pride ourselves in not only high success rates, but the dependability of our work, and this new build and testing center will even further our capabilities in the work that we do.

“With our new testing center, we are granted the opportunity to fully build and test systems well before anything is ever deployed, streamlining the process. By conserving on-site and installation time, a key ingredient to higher success rates, pre-configuring and programming in advance awards each system the time they truly deserve, in turn making us, and the client, gratified with the results.” – Eric Bowman, System Master Builder & Travis Staker, Systems Programmer

Benefits of our new build and testing center:

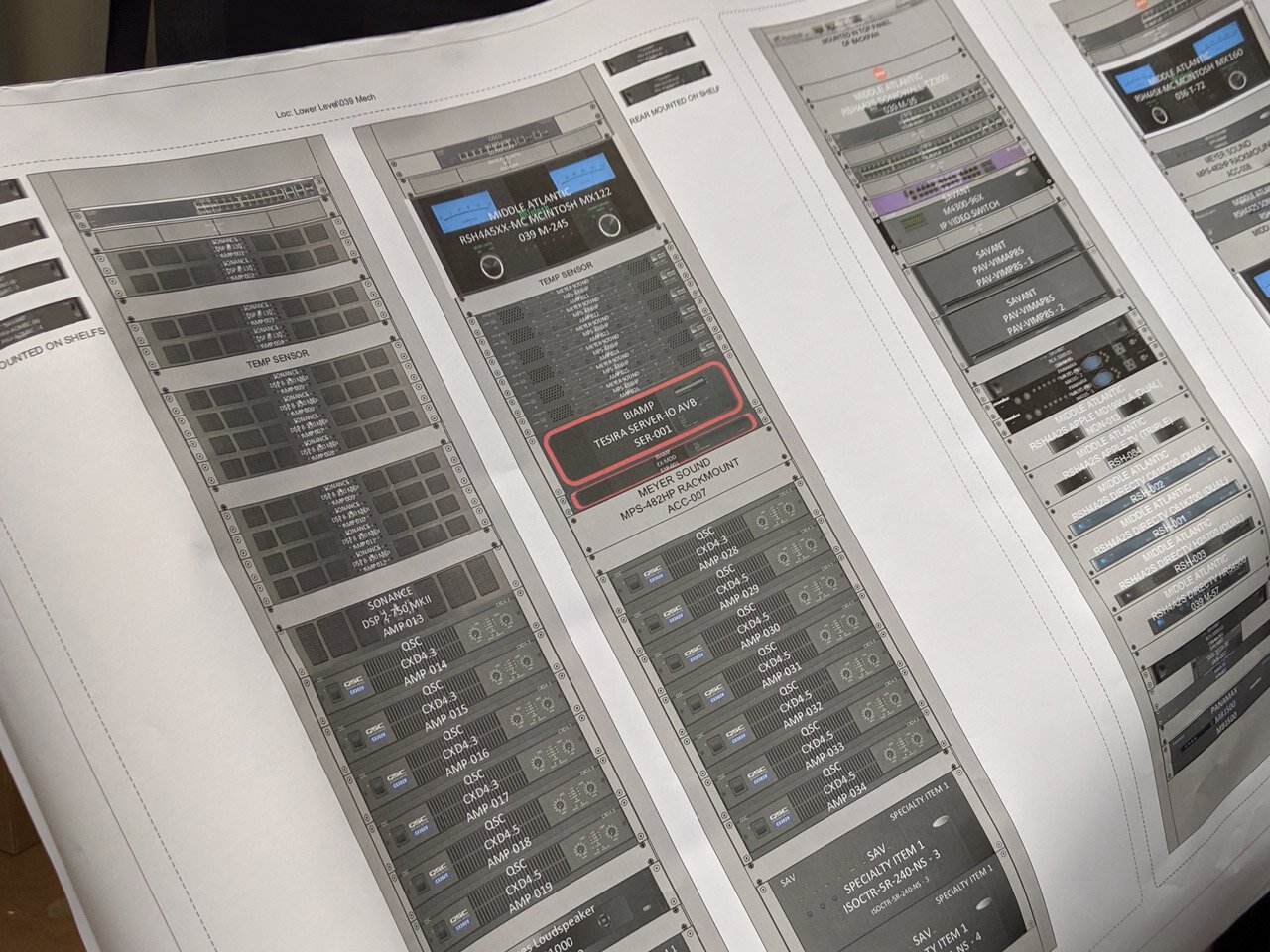

Capability to fully install up to 4 systems at one time. This allows for full programming and the testing of systems well before deployment.

Over 25,000 feet of low-voltage wire used in all of the testing [4.75 Miles]

Pre-programming of surveillance systems and testing before installing them in any environment.

Access control testing board for testing up to 3 automated locks at a time.

The ability to have a functioning network prior to the installation of the equipment rack.

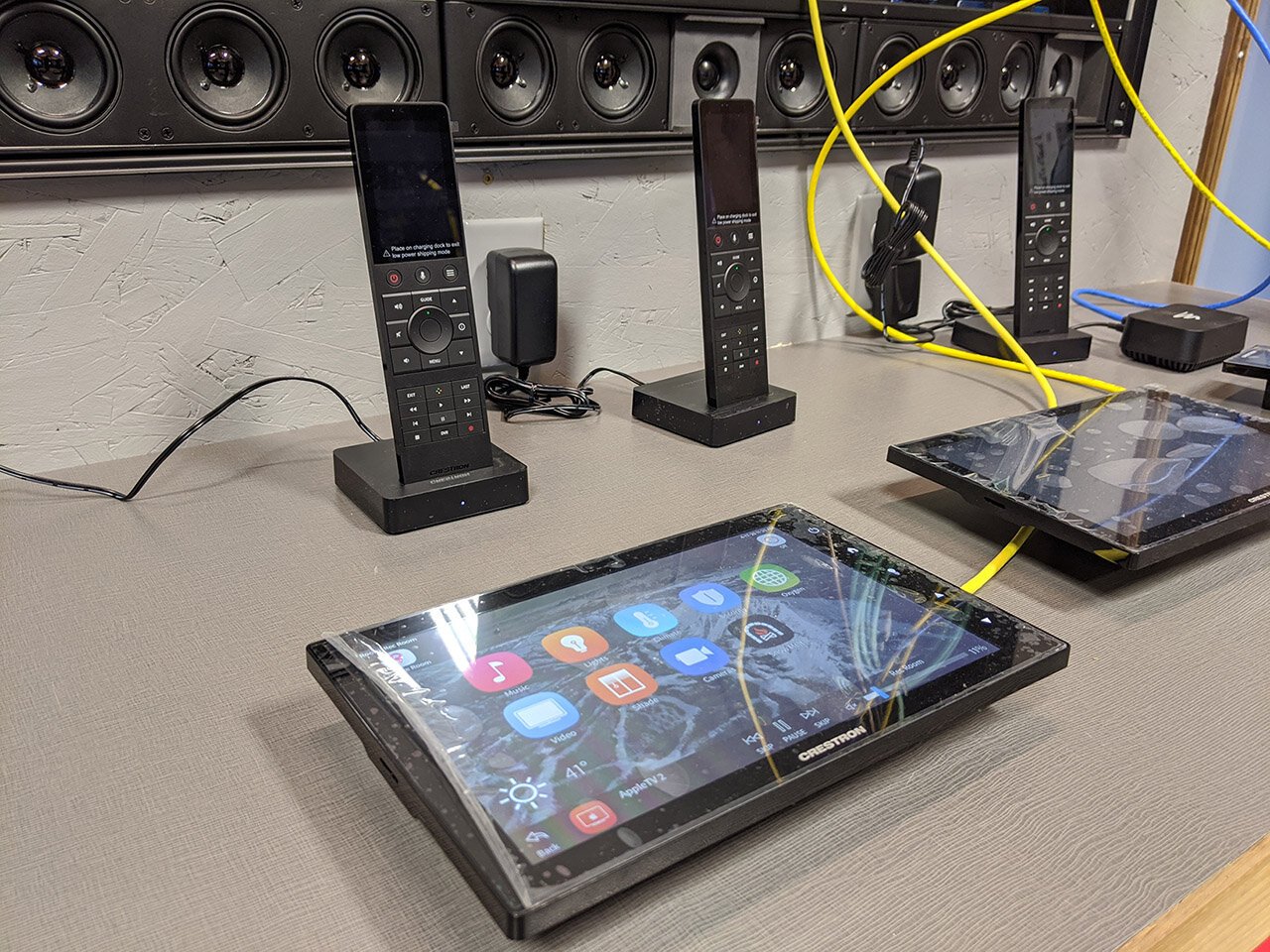

Support up to 12 video zones, ranging from simple local systems to fully distributed video over IP with fiber optic.

110-inch film screen with fully adjustable projector mount for testing throw distance and projector calibration.

32 zones of audio testing, including two in-wall and eight floor-standing subs. Full 7.2 surround audio zone testing.

Full Lutron lighting system with 32 separate zones of lighting for in-house programming and testing.

88 Audio/Video and lighting keypads for full configuration of the control system.

4 back box locations for mounting equipment, allowing technicians to have preloaded back boxes that they can simply plug and play.

“I always felt like there must be a better way to design, test and deliver the systems we do. So, our Team spent almost 2 decades designing, using and perfecting the Millson FrameWork to create an efficient, repeatable and proven process for doing just that. Now we are sharing this with others, and it is both deeply gratifying and truly humbling to see some of the very best Integrators in the nation adopt and use it. SAV has always been known throughout the industry as a true pioneer, always looking to improve and deliver the very best solutions and customer experience possible. I am thrilled that Cory and his Team are now incorporating our FrameWork solutions to add even more efficiency, speed and accuracy to their process and the systems the deliver for their clients.” – Richard Millson, Millson Technologies